|

|

MENU HERE

Programming Instructions for Remote Controls Openers and Remote Switches

LRT1, LRT-1 Programmable Remote Control Controller

***Click Here to add a tracking number to your order***

Operation & Programming Instructions for the LRT1 Programmable Remote

This programmable remote control (

remote) can duplicate a majority of fixed code remote controls.

A fixed code remote control is one that transmits the same frequency, or code each time the button is pressed.

This unit can duplicate the frequency as long as the original remote control operates between the frequencies of 251-538 Mhz and the remote does not utilize Code Hopping or Anti-Code Grabbing Technology, which changes frequency each time the button is pressed.

It is not possible to copy any remote that utilizes Code Hopping or Anti-Code Grabbing Technology. This is because these types of remotes send a different code each time the remote is pressed.

The

remote has four buttons that can each be used for multiple functions. The same code can be copied onto multiple buttons if desired. Alternatively, you can program the remote with a different code for some or each button to operate multiple devices from one remote. If your original remote has a function controlled by pressing multiple buttons together, you must duplicate that code to a single button on your

remote. You can also copy multiple remotes onto the one

remote, provided they all operate on the same frequency

PROCEDURE TO AUTOMATICALLY DUPLICATE THE FREQUENCY OF YOUR REMOTE

1. Determine the frequency of your original remote control unit.

By FCC regulation, this should be printed on the back of the unit and is indicated in MHz (megahertz).

You may also refer to the following chart to see if your unit is listed

|

Chamberlain

Genie, Sears

Lift-Master

Master Mechanic

Wayne Dalton

|

390 MHz |

|

Pulsar

|

318 MHz |

|

Master Craft

|

315 MHz |

|

Linear

Moore-O-Matic

Stanley Multi-Code

|

310 MHz |

If you cannot find the frequency of your unit, you may have to contact the manufacturer to determine the frequency that the remote control unit operates at.

You can also try the trial and error method, but that can be very time consuming since the programming usually requires several tries to be successful.

Note: If the frequency is not between 251 and 538 MHz, the

remote cannot duplicate the frequency.

2.

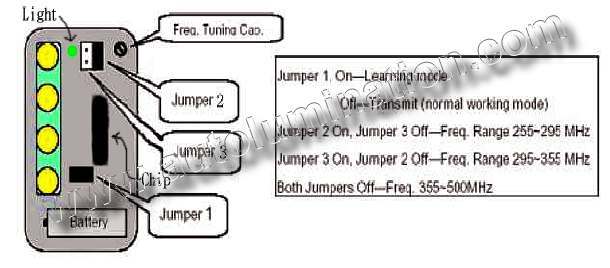

Once you determine the frequency of your remote control unit, you must arrange the jumpers on the

remote per the table below in order to match the frequency of your original remote control in order to program the

remote

.

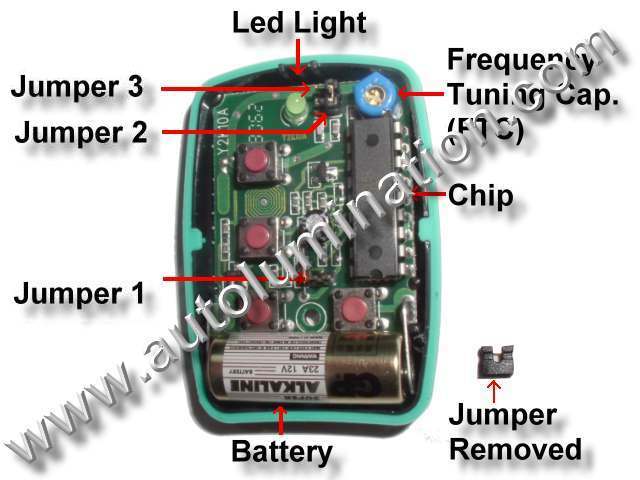

Check the position of each of the three jumper locations in the

remote after removing the cover of the

remote

.

The cover can easily be removed by pulling the two halves of the plastic case apart. Use the tool provided to pry in between parting lines to help separate the two halves of the plastic case.

There are 3 jumper locations and two plastic jumpers in each

remote

.

The jumpers can be removed or installed onto the jumper pins with a pair of needle nose pliers or tweezers.

Arrange the jumpers to match the table shown below.

Jumper location 1 On – Learning Mode

Jumper location 1 Off – Transmit (normal working mode)

(Note the

remote will not transmit in learning mode and will not program in operating mode):

Program Mode:

|

Frequency Range |

Jumper 1 |

Jumper 2 |

Jumper 3 |

|

251~294 MHz |

On |

On |

Off |

|

295-355 MHz |

On |

Off |

On |

|

355-538 MHz |

On |

Off |

Off |

|

|

3.

Place the

remote and original transmitter right next to one another on a flat non-metallic surface, or back to back in one hand.

4. Once you have the units arranged so the chips are as close to one another as possible, press & hold down the button on the original remote that you wish to program onto button 1 of the

remote, and then immediately press & hold down the button on the remote that you want to program. The green

remote light should light up green briefly and then go dark briefly.

Hold both buttons down until you see the green light on the

remote pulse three times.

This should only take ~ 5-10 seconds.

If you do not see the three pulses, you have not successfully duplicated the code from the original remote.

In some cases, this may take several tries before the code will be recognized and stored onto the

remote

.

If you do not see the green light pulse three times, repeat step 4 until the green light pulses 3 times.

Steps to take if you cannot get the green light on the remote to pulse three times after repeated attempts:

A. Ensure that the chip side of the remote is arranged so that it is as close to the original remote as possible. Ensure that the original remote is arranged so that the chip in the original remote is as close as possible to the remote chip Rotate one or both units to get the chips physically as close as possible .

B. If the green light on the remote will not light at all, check to ensure the battery is in and that the battery is not backwards (+ should be towards the buttons on the remote).

C. Ensure that the jumpers are all correct (see step 2).

D. If all else fails, use the tool provided to make minor adjustments to the Frequency Tuning Cap. (FTC). While holding down the button on the remote and the button on the original remote, turn the screw in the FTC very slowly clockwise and then counterclockwise until the green light on the remote pulses 3 times. Once you see the light pulse 3 times, make a note of which button you have programmed for that remote. Remember not to reprogram that button, or you may lose the code and have to reprogram it again.

The FTC will change the frequency at a rate of +/-60 mhz for each 1/2 revolution, so it is very sensitive. Usually the frequency only is off by about 10 mhz, so you may only need to move the FTC 1/8 turn one direction or the other to move 10 mhz.

Examples:

For frequency range 295-355, if you turn the FTC 180 degrees (1/2 turn in either direction) it will move +/-60 mhz, so if it was at 295 mhz and you turn it 180 degrees it will go to 355 mhz.

If it was at 325mhz and you turn it 180 degrees (1/2 turn), it will be at 325 mhz.

If you turn the FTC 90 degrees it will change the frequency ~+/-30 mhz. If you rotate the FTC 360 degrees, it will return back to the original frequency.

5. Repeat steps 1-4 for buttons 2, 3, & 4 on the remote if desired.

Note: After all of the buttons have been programmed, the unit will not yet transmit a signal, and it will not operate properly until step 6 is completed.

6.

Remove Jumper 1 near the battery. This activates the unit and it is now in normal working mode.

The

remote now will not be reprogrammed and the remote will now transmit and operate.

CAUTION: DO NOT LOSE THE JUMPERS.

Place the unused jumpers over just one pin so you will not lose the jumpers. Alternatively, you can leave the jumpers loose inside the remote.

You may need the jumpers again someday, if you have to reprogram the

remote.

As long as the jumper is only installed over a single pin at the jumper position, it will not activate that jumper position and can be stored there safely for future use, if required.

7. After you verify that the remote operates properly for each device you have programmed it for, replace the cover and screw closed using the tool and screw provided. Do not over tighten. The procedure is now completed.

FCC Caution:

This device complies with part 15 of the FCC Rules. This operation is subject to the following two conditions. (1) This device may not cause harmful interference and (2) this device must not accept an interference that may cause undesired operation.

Note: If you get the remote light to pulse 3 times, but the remote will still not operate your device, or if the range of the remote in not sufficient, you may have to complete the following additional adjustments (First verify that jumper 1 has been removed. The remote will not transmit if jumper one is across both pins) :

TO MANUALLY ADJUST THE remote AND FINE TUNE THE FREQUENCY, FOLLOW THESE STEPS

1. Re-open the case of the remote using the tool provided. Replace Jumper 1 (Learn Mode).

2. Identify the frequency tuning capacitor (FTC). Refer to diagram.

3. Place the remotes together with the chips as close as possible. Press and hold down a matching button on each remote using two fingers from one hand (with a little practice you can do this yourself, or you may need a helper). Now part your fingers so as to slowly increase the distance between the remotes to the point where the green remote light becomes most dim, but is still visibly lit. As you do this, you may notice that the remote reprograms itself. After it reprograms itself (as indicated by the 3 pulses), the light will stay lit solid for only a few seconds. During this brief period,

Use the tool provided to turn the screw in the FTC very slowly clockwise and then counterclockwise until the green light on the remote glows brightest.

Once the FTC is adjusted to make the light as bright as possible, you have maximized the range of the remote for that device.

During this process, you may notice that the remote will not reprogram, or loses it's program. This is caused by the FTC being adjusted too much or in the wrong direction. To correct, place the units

The FTC will change the frequency at a rate of +/-60 mhz for each 1/2 revolution, so it is very sensitive. Usually the frequency only is off about 10 mhz, so you may only need to move the FTC 1/8 turn one direction or the other to move 10 mhz.

Examples:

For frequency range 295-355, if you turn the FTC 180 degrees (1/2 turn in either direction) it will move +/-60 mhz, so if it was at 295 mhz and you turn it 180 degrees it will go to 355 mhz.

If it was at 325mhz and you turn it 180 degrees (1/2 turn), it will be at 325 mhz.

If you turn the FTC 90 degrees it will change the frequency ~+/-30 mhz. If you rotate the FTC 360 degrees, it will return back to the original frequency.

IMPORTANT: After this process, be sure to remove Jumper 1 before trying to operate the remote. The remote will not transmit if Jumper 1 on both pins.

4. If you do not know the frequency range of your remote, try another Frequency Range by changing configuration of Jumper 2 & 3 and repeat the programming steps .

|

Frequency Range |

Jumper 1 |

Jumper 2 |

Jumper 3 |

|

251~295 MHz |

On |

On |

Off |

|

295-355 MHz |

On |

Off |

On |

|

355-538 MHz |

On |

Off |

Off |

5. Once successful, operating range can be maximized by moving to the furthest distance from the remote controlled device where the remote signal will still make the remote controlled device function. Take two steps backwards and minutely adjust the FTC in either direction until the alarm arms again. Repeat this procedure until maximum range is achieved.

6. Replace the case and screw it closed. Do not over tighten. The procedure is now complete.

UPIC Shipping Insurance

Note: Our packages are not automatically insured against loss during shipping. Insurance is the responsibility of the purchaser!

$2.00 for each $100 unit of insurance

Shipping Insurance

$2.00 per $100

|

Powered by Ewebmerchant.com |